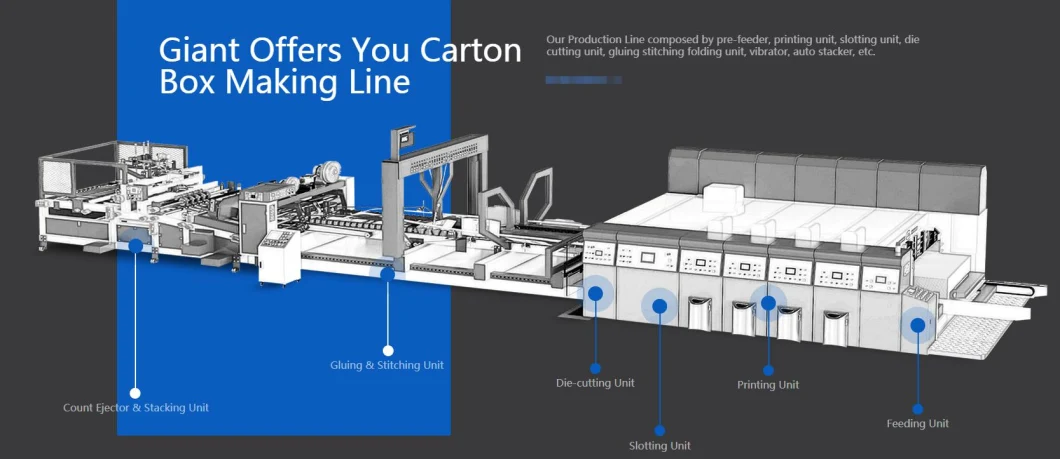

Flexo Printer Slotter Die Cutter & Folder Gluer Stitcher Corrugated Box Maker

Product Machine features

*lead edge feeding system. ( lead edge vacuum roller feeding system. )

*top / bottom printing system.

*single or dual slot system

*high quality material with suitable fittings is used for the machine.

*the drive gears adopt alloy steel, and then heated to ensure hardness, with grinded surface.

*all the lower feeding roller used a bigger diameter to increase touch area of paper, to ensure fluent processing and accurate printing.

*there are oilless bearings between frame and eccentric gear seat to reduce wear-out of frame and increase machine using life.

*we adopt no-key connection(means swelling connection) to reduce printing inaccuracy.

*according to international security standard, all the parts are with safety angles and all the motors with protective cover.

*all the rollers adopt superior material with hardness and thickness chrome and two times grinding, and passed balance testing.

*automatic return to zero position.

*the machine is designed according to high requirement, reliability, safety and beautiful feature, automatic change / save order and easy to operation.

*all the rollers are plated with chromium to enhance hardness.

*adopt PLC with touch screen for multifunction control, automatic reset system after cleaning the printing plate.

*most of the electric parts we use are from international famous brands.

*special design and superior quality will meet your requirement.

*machine control system is developed by Korea engineers, where workers are easy to learn and operate.

Specifications for each units

1. Feeder unit

1.1 technicanl parameter

* detail technical parameter can be provide if need

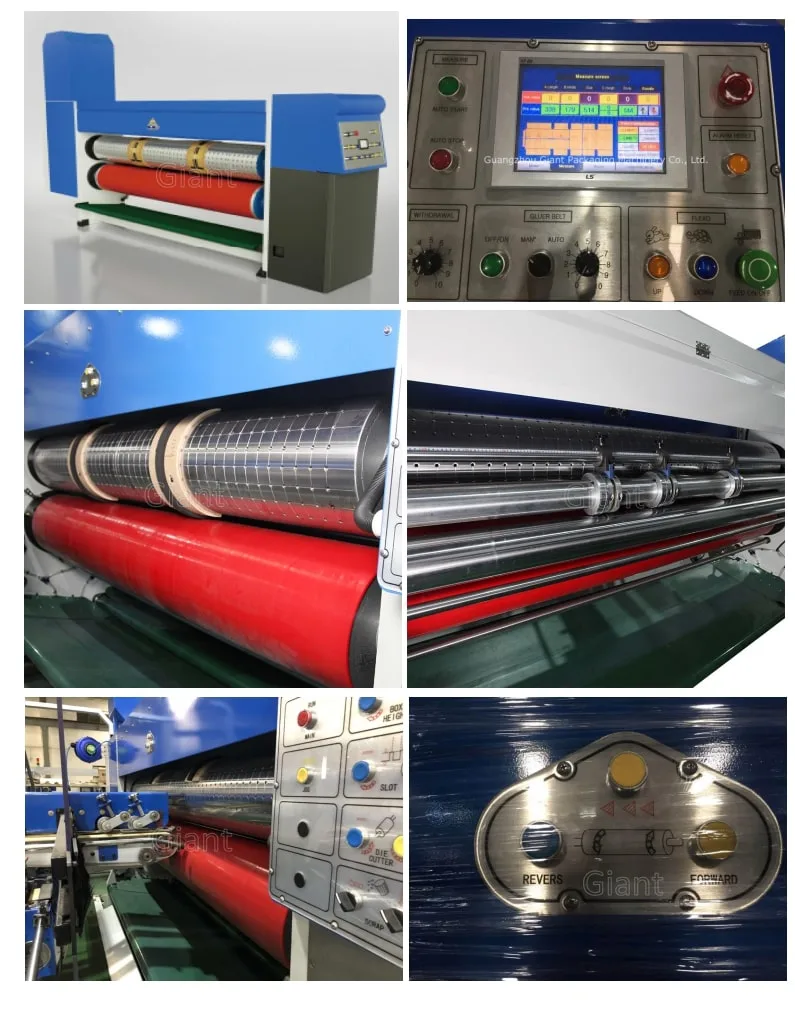

1.2 photo

2. Printer unit

2.1 technicanl parameter

* detail technical parameter can be provide if need

2.2 photo

3. Slotter unit

3.1 technicanl parameter

* detail technical parameter can be provide if need

3.2 photo

4. Die-cutter unit

4.1 technicanl parameter

* detail technical parameter can be provide if need

4.2 photo

5. Gluer / stitcher folder & count ejector unit

5.1 technicanl parameter

* detail technical parameter can be provide if need

5.2 photo

Carton Photos

About Giant

Giant Packaging Machinery company is the manufacturer of carton making machine, such as flexo printing, slotting, die-cutting, glueing, stitching, folding, etc.

Giant is a wholly Korean-owned enterprises, factory at Korea & China.

Giant machines all have national patents and CE certification, already passed audit by BV, SGS.

You May Like

More Videos for Different machines

1. Inline machine - flexo printer slotter die-cutter folder gluer counter ejector

https://youtu.be/QMTbNGaZ7O0 (top printing)

https://giantgiant.en.made-in-china.com (bottom printing)

2. Auotmatic gluer foler machine

https://youtu.be/GRJ0d_UZnJg

3. Automatic gluer stitcher folder machine

https://youtu.be/zL-4Qnei01w

4. Flexo Printing, slotting, die-cutting, stacking. Machine at Saudi Arabic

https://youtu.be/6EYdSy_hJJE (1200*2400, 3 colors printer slotter die-cutter vibrator stacker)

https://youtu.be/duEVMdIKZ-M (1800*5000, 3 colors printer slotter die-cutter stacker)

5. Pre feeder

https://giantgiant.en.made-in-china.com

6. Korean factory design

https://youtu.be/ntmoxq1Rv_M (design a new carton plant)7.

7. Machine operation

Https://youtu.be/owHZMWND618 (machine setup)

* Contact us for more information

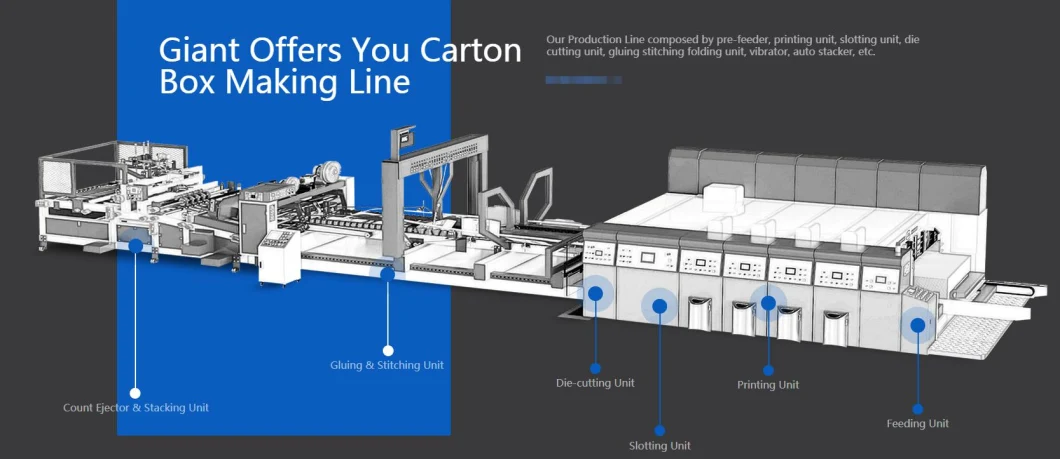

Product Machine features

*lead edge feeding system. ( lead edge vacuum roller feeding system. )

*top / bottom printing system.

*single or dual slot system

*high quality material with suitable fittings is used for the machine.

*the drive gears adopt alloy steel, and then heated to ensure hardness, with grinded surface.

*all the lower feeding roller used a bigger diameter to increase touch area of paper, to ensure fluent processing and accurate printing.

*there are oilless bearings between frame and eccentric gear seat to reduce wear-out of frame and increase machine using life.

*we adopt no-key connection(means swelling connection) to reduce printing inaccuracy.

*according to international security standard, all the parts are with safety angles and all the motors with protective cover.

*all the rollers adopt superior material with hardness and thickness chrome and two times grinding, and passed balance testing.

*automatic return to zero position.

*the machine is designed according to high requirement, reliability, safety and beautiful feature, automatic change / save order and easy to operation.

*all the rollers are plated with chromium to enhance hardness.

*adopt PLC with touch screen for multifunction control, automatic reset system after cleaning the printing plate.

*most of the electric parts we use are from international famous brands.

*special design and superior quality will meet your requirement.

*machine control system is developed by Korea engineers, where workers are easy to learn and operate.

Specifications for each units

1. Feeder unit

1.1 technicanl parameter

| Feeding system | Lead edge feeding system |

| Zero position | Automatic |

| Total counter | Touch screen display |

| Machine speed | Touch screen display |

| Sheet clearer | Suction bolower & brush for sheet cleaning |

| Side guide position | Motorized, 0.2kw×2ea, touch screen display |

| Front stop position | Motorized, 0.1kw, by jog switch |

| Back stop position | Motorized, 0.2kw, by jog switch |

| Feed roll nip control | Motorized, 0.2kw, touch screen display |

| Unit open/close | Motorized, 0.4kw, by jog switch |

| Lower suction blower | 7.5 kw |

| Main motor | Inverter control: 37kw |

1.2 photo

2. Printer unit

2.1 technicanl parameter

| Top printing system | Optional |

| Bottom printing system | Optional |

| Vacuum transfer system | Optional |

| Ceramic anilox roller | Optional |

| Chamber doctor blade | Optional |

| Doctor roller inking system | Diaphragm type ink pump |

| Register system | Printing register is digital controlled by motor and PLC |

| Easy to control by means of reset "0" system | |

| Zero position | Automatic |

| Print cylinder register | Motorized 0.4kw, touch screen display |

| Print cylinder side control | Motorized 0.2kw, touch screen display |

| Impress roll nip control | Motorized 0.2kw, touch screen display |

| Pull roll nip control | Motorized 0.2kw, touch screen display |

| Anilox roller clearance | Motorized 0.1kw, touch screen display |

| Doctor roller clearance | Motorized 0.2kw, touch screen display |

| Doctor roller motor | Geared 0.4kw |

| Gear box oil level | Automatic control (all unit the same) |

2.2 photo

3. Slotter unit

3.1 technicanl parameter

| Dual slot system | No need mechanical adjustment for bigger carton height |

| Zero position | Automatic |

| Panel size | Motorized(0.4kw X 4ea), touch screen display |

| Slot depth size | Motorized(0.4kw), touch screen display |

| Box height size | Motorized(0.4kw), touch screen display |

| Cleaser nip control | Motorized, 0.2kw, touch screen display |

| Slotter nip control | Motorized, 0.2kw, touch screen display |

| Scrap conveyor | 0.4kw |

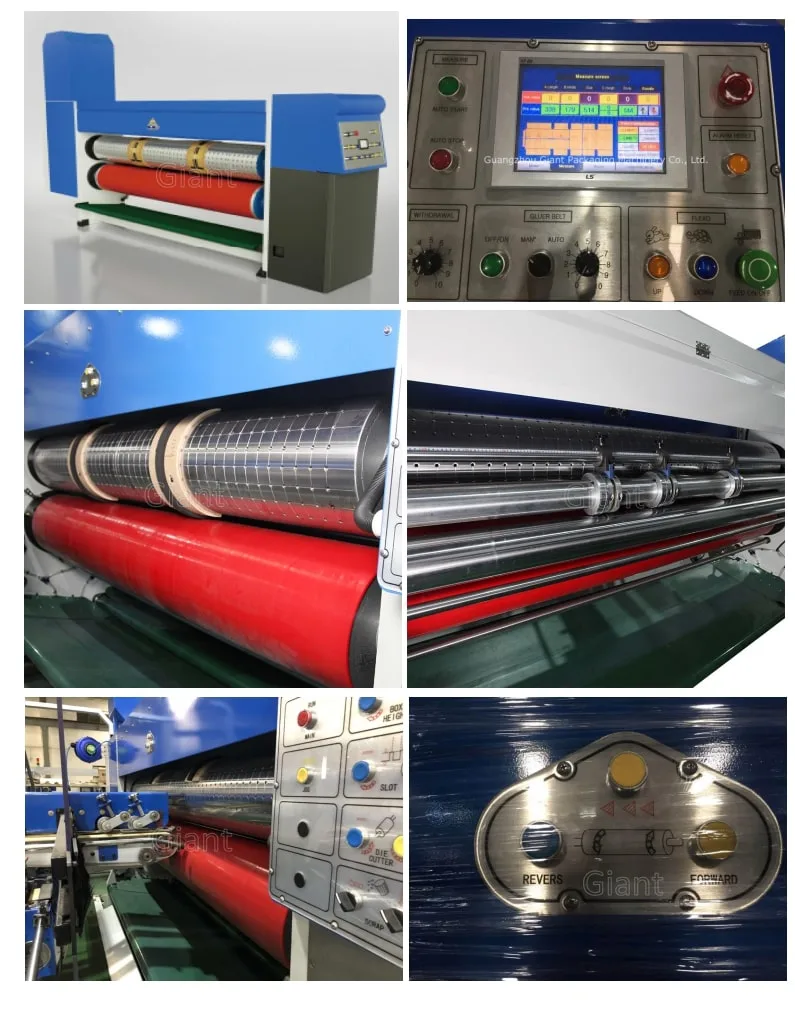

3.2 photo

4. Die-cutter unit

4.1 technicanl parameter

| Zero position | Automatic |

| Die roll register | Motorized 0.4kw, touch screen display |

| Die roll side control | Motorized 0.2kw, touch screen display |

| Anvil roll transversal movement | Automatic 70mm |

| Anvil roll clearance | Motorized 0.4kw, touch screen display |

| Pull roll nip control | Motorized 0.2kw, touch screen display |

| Scrap conveyor | 0.4kw |

4.2 photo

5. Gluer / stitcher folder & count ejector unit

5.1 technicanl parameter

| Down folding system | Optional |

| Up folding system | Optional |

| Belt transportation system | With guide bar leads the carton box and makes folding mor accurate |

| Box squaring system | |

| Main motor | AC 15kw, inverter control |

| Side guide positation | 0.4kw X 2ea, touch screen display |

| Glue head position | 0.4kw X 1ea, touch screen display |

| Pusher | 0.75kw |

| Suction blower | 2.2kw X 2ea, 1.5kw X 1ea |

| Bottom stacking system | The boxes stack from bottom to top |

| Suction belt conveyor | For the best conveying accuracy |

| Count ejector system | For high speed production |

| Main motor | 7.5kw |

| Front stop position | 0.4kw, touch screen display |

| Back stop position | 0.4kw, touch scereen display |

| Ejecting line control | Touch screen display |

| Center line control | 0.4kw |

| Suction blower | 2.2kw |

| Belt conveyor | 0.75kw |

5.2 photo

Carton Photos

About Giant

Giant Packaging Machinery company is the manufacturer of carton making machine, such as flexo printing, slotting, die-cutting, glueing, stitching, folding, etc.

Giant is a wholly Korean-owned enterprises, factory at Korea & China.

Giant machines all have national patents and CE certification, already passed audit by BV, SGS.

You May Like

More Videos for Different machines

1. Inline machine - flexo printer slotter die-cutter folder gluer counter ejector

https://youtu.be/QMTbNGaZ7O0 (top printing)

https://giantgiant.en.made-in-china.com (bottom printing)

2. Auotmatic gluer foler machine

https://youtu.be/GRJ0d_UZnJg

3. Automatic gluer stitcher folder machine

https://youtu.be/zL-4Qnei01w

4. Flexo Printing, slotting, die-cutting, stacking. Machine at Saudi Arabic

https://youtu.be/6EYdSy_hJJE (1200*2400, 3 colors printer slotter die-cutter vibrator stacker)

https://youtu.be/duEVMdIKZ-M (1800*5000, 3 colors printer slotter die-cutter stacker)

5. Pre feeder

https://giantgiant.en.made-in-china.com

6. Korean factory design

https://youtu.be/ntmoxq1Rv_M (design a new carton plant)7.

7. Machine operation

Https://youtu.be/owHZMWND618 (machine setup)

* Contact us for more information