YIKE GROUP Automatic corrugated carton box flexo printer slotter die cutter machine

Lead-edge Feeding System

cardboard or thin cardboard high-speed accurate transmission.

Machine Separation & Combination

while host normal working conditions, the unit clutch function is automatically lock, to avoid machine misuse and personal injury.

Dust-removal System

Feeding Roller: double Feeding Roller

2.Printer Unit

Printing Roller

Pressing Roller

Anilox Roller

First Priner Unit:

Feeding Roller

Phase Adjust System

Phase Fix System

Zero Device

4.Die-cutting Unit

1. Feeder Unit

Lead-edge Feeding System

- Lead-edge suction feeding system, easy operation, high accuracy,(adopts lead feeder system).

- 7.5KW high pressure centrifugal fans, according to the cardboard

cardboard or thin cardboard high-speed accurate transmission.

- Left and right side baffle position electrically adjustable,

- Front baffle adjust the position of the upper and lower intervals

- Skip-feeding devices, could select skip-feeding according to needs. To ensure that large-scale cardboard can also be processed.

- Install 7" touch screen, could automatically display the

- Slotting part is equipped with the interlock switch, to achieve the

Machine Separation & Combination

- Button switches electrically control the separation and combination

- Air pressure interlocks, lock securely, conveniently and accurately.

- Machine clutch drive shaft is equipped with overload protection device.

- Active self-locking function: if unit is not completely locking state,

while host normal working conditions, the unit clutch function is automatically lock, to avoid machine misuse and personal injury.

Dust-removal System

- Adopt brush cleaning device, equipped with strong Negative pressure suction fan, clearing the dust, paper scrap or other waste, to improve printing quality.

Feeding Roller: double Feeding Roller

- Upper feeding roll adopts outer diameter φ165mm rubber roller,

- Lower feeding roller adopts embossed rollers, hard chrome-plated, wear and smooth.

- According to cardboard thickness, adopt worm gear box gap tuning, with locking device. Adjustment range 0-12mm

2.Printer Unit

Printing Roller

- With printing plate

- High quality steel production, surface grinded, hard chromium-plated. Static balance adjustment, stable operation, suitable for high speed running

- Roller horizontal direction and circumferential direction with datum line, convenient for align plate

- Fixed coil axis, suitable for standard hanging slats, realize rapid change plate

- Electric 360° adjust printing roller, automatic digital display adjustment,remember store digital.

- Installed with foot switch to control plate roller reversing, convenient change plate

- Auto-zero function,order memory.

- Printing roller plate-change and fix-plate function.

- Printing roll axial is adjusted left and right by manual,maximum movement left and right 10mm,auto-zero instruction.

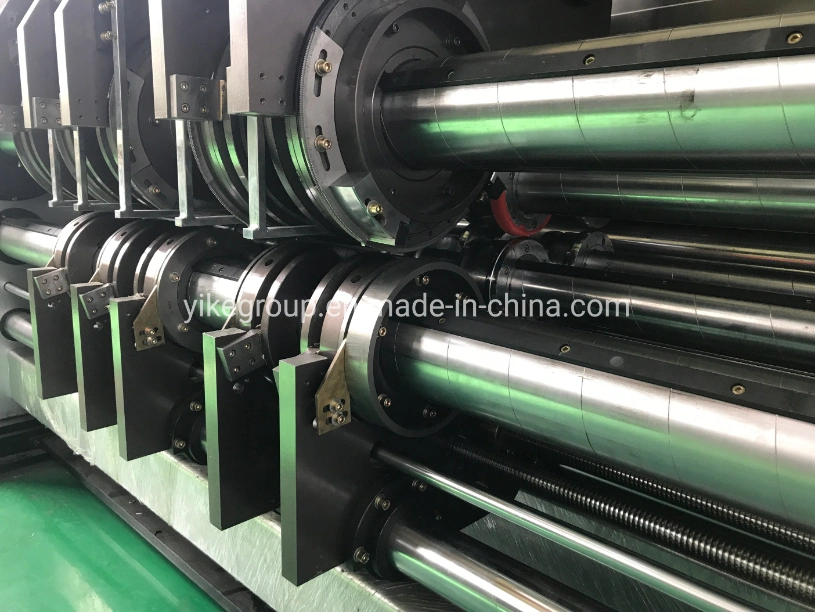

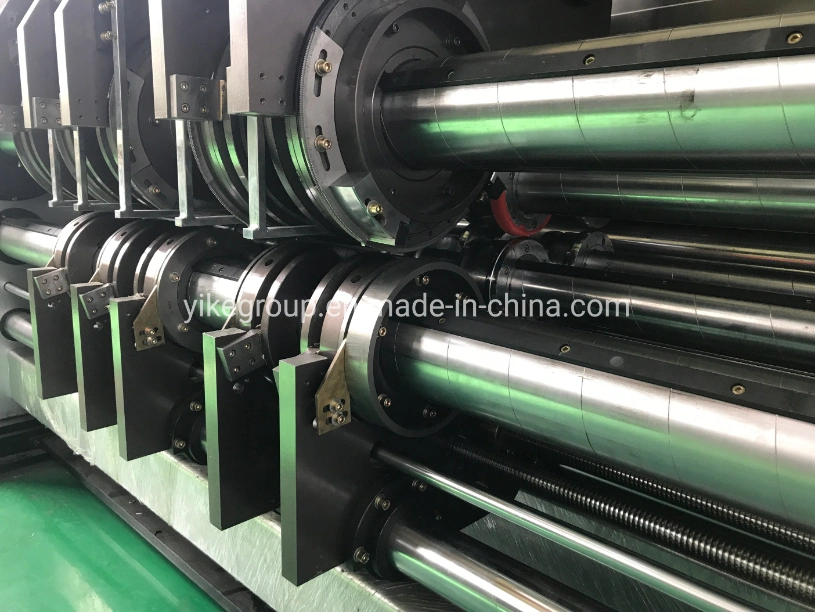

Pressing Roller

- Adopt high quality seamless delicately processing, dynamic balance adjustment, stable operation

- Surface grinded, hard chromium-plated

- Gear adopt backlash adjustment mechanism, adjustment none-affect gear enunciation, guarantee transmission accuracy

- Printing roller can be adjusted for a distance 0-12mm

- pressing roller, feeding shaft can be adjusted by manual , and loose and tight the roller also by manual.

Anilox Roller

First Priner Unit:

- Steel anilox roller, brand HAILI

- Steel anilox roller mesh:150-300 line

- Rubber roller adopts Guangdong Jingyang.

- Overrunning clutch and automatic idling device, to prevent the ink dried

- Rubber roller drum type middle part higher, to ensure ink quality

- Rapid spaced spinner self-locking device, ensures uniform ink

- Ink distributing roller independent drive mechanism, ensure ink quality

Feeding Roller

- Feeding roller four wheels feeding

- Feeding roller gear adopts no-side-gap regulating mechanism, can adjust the interval of 12mm

- Hand adjustable rapid clearance adjustment self-locking device, fast, reliable.

- Pneumatic diaphragm pump, simple operation, convenient maintenance, supply stability

- Circulating pneumatic ink

- Screen for filtering impurities, guarantee printing quality

Phase Adjust System

- Planetary gear structure

- Digital computer 360 ° adjustment, both running and stopping state conditions

- Printing phase adjustment of PLC computer display adjustment

- After units separate, automatic reset system (eraser memory)

Phase Fix System

- Pneumatic brake device, Unit separation and combination or phase adjustment, original point of transmission gear with constant

Zero Device

- Auto-zero device, to ensure that the units have a uniform adjusted basis, reducing cardboard waste,edition memory function.

3.Slotting Unit

- Single-axle double-knife slotter, use Internal tooth structure adjutment the height of box, So that oil does not easily contaminated cartons

- The first pressure line round, after preloading cardboard not easily crush

- The above press round Urethane appearance package, will not damage the cardboard

- The slotter knife stock use traverse mechanism, screw with linear guide, to move more flexible and precise

- Slotting phase and box height, computer and electric digital control

- Preload, creasing gap adjustment adopt computer and electric digital control

- The slotter knife stock gap adjustment adopt self-locking structure

- There's the elastic corner-cutting knife. Can cut three, five, cardboard without adjusted.

- Preload wheel, creas wheel, slot knife traverse position computer and electric digital control

- The slotter knife adopt Anti-knife manner

- Computer automatic arrange knife, can stockpile 999 memories

4.Die-cutting Unit

- Rubber roller mechanical spiral commutation 40mm move about horizontal structure

- Die-cutter phase, computer and electric digital control

- Horizontal phase, computer and electric digital control, range ±5mm

- Rubber roller and die roller gap use computer and electric digital control,

- Adjust the transfer roller use computer and electric digital control,

- The rubber roller compensated by motor-driven,control the speed of thr rubber roller, range ±3mm

- Rubber roller hsiuping cutting structure, keep rubber surface roughness

- Stripping the belt longitudinal output, to easy clean waste paper.