SPECIFICATION:

DESCRIPTION:

1.Feeder section

*Equipped with vibrating motor;

*With independent transmission, low noise, with front adjustable wheels, max working capacity can be achieved;

*Feeding knives and left and right registers fixing bar are controlled up and down by pneumatic system easily;

*Feeding knives are equipped with pneumatic mechanism for feeding.

2.Paper alignment system

*Automatic alignment system to correct the paper feeding, avoiding the paper going to sides;

3.4/6 Corner section

*This system adopts Japanese Yaskawa servo system, which can adjust the running trajectory for the hook to suit for the folded length, also finished the hook backward working, therefore, lock bottom, front hooking and back hooking etc can be achieved to meet different boxes, advanced design;

*There are left, middle and right carriers, which can be easily dismantled to meet the demand for different boxes;

*Lock-bottom section of modular design reduces the adjusting time for different boxes, and enhances the change-over time for installing attached parts;

4.Lock-bottom section

*Lock-bottom assembly mechanism with high elastic hookers is of ideal design, fast and easy operation;

5.Lower gluing tank

*Big-volume design, when the machine is running at high speed, the glue will not go out or leaking, optional bottle is good for long time operation;

6.Folding section

*Equipped with speed variator for belts, ensure the folded boxes parallel and in good order;

*Fast, convenient adjustment and operation can fold boxes perfectly;

*The middle up and down transmission module can fold the boxes synchronously or alternately.

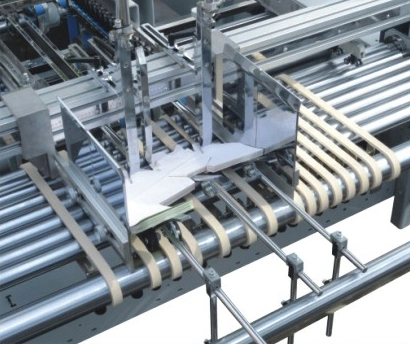

7.Trombone section

*Pressure can be adjusted according to paper thickness. For flute A, B corrugated board, overlapping and jogger devices are equipped to ensure box gluing well. After kicker is set up, whatever speed the machine runs, the kicker can automatically follow, no need to reset it.

8.Conveyor section

*Pneumatic pressure increasing, speed and pressure can be independently adjusted, pressure could be as bit increased on boxes, so the finished boxes will be more beautiful;

*The front section of conveyor can coordinated with overlapping and jogger devices to move up and down suitably.

| Materials | Paperboard, A, B, E corrugated board |

| Box shape | Straight line, double sided, lock-bottom box |

| Straight line | FG-1200C 4/6: 1200X800mm(max.); 200x200mm(min.) FG-1500C 4/6: 1500X1100mm(max.); 400x200mm(min.) |

| Double sided | FG-1200C 4/6: 1200X800mm(max.); 200x200mm(min.) FG-1500C 4/6: 1500X1100mm(max.); 400x200mm(min.) |

| Lock-bottom | FG-1200C 4/6: 1200X800mm(max.); 200x280mm(min.) FG-1500C 4/6: 1500X1100mm(max.); 400x280mm(min.) |

| 4-corner box | FG-1200C 4/6: 1000X800mm(max.); 300x300mm(min.) FG-1500C 4/6: 1300X800mm(max.); 300x300mm(min.) |

| 6-corner box | FG-1200C 4/6: 1000X800mm(max.); 400x400mm(min.) FG-1500C 4/6: 1300X800mm(max.); 400x400mm(min.) |

| Max. speed | 0-250m/min |

| Total power | FG-1200C 4/6: 27kw FG-1500C 4/6: 32kw |

| Machine size and weight | FG-1200C 4/6: 16900x2200mm(LxW), 9tons FG-1500C 4/6: 17500x2400mm(LxW), 11tons |

DESCRIPTION:

1.Feeder section

*Equipped with vibrating motor;

*With independent transmission, low noise, with front adjustable wheels, max working capacity can be achieved;

*Feeding knives and left and right registers fixing bar are controlled up and down by pneumatic system easily;

*Feeding knives are equipped with pneumatic mechanism for feeding.

2.Paper alignment system

*Automatic alignment system to correct the paper feeding, avoiding the paper going to sides;

3.4/6 Corner section

*This system adopts Japanese Yaskawa servo system, which can adjust the running trajectory for the hook to suit for the folded length, also finished the hook backward working, therefore, lock bottom, front hooking and back hooking etc can be achieved to meet different boxes, advanced design;

*There are left, middle and right carriers, which can be easily dismantled to meet the demand for different boxes;

*Lock-bottom section of modular design reduces the adjusting time for different boxes, and enhances the change-over time for installing attached parts;

4.Lock-bottom section

*Lock-bottom assembly mechanism with high elastic hookers is of ideal design, fast and easy operation;

5.Lower gluing tank

*Big-volume design, when the machine is running at high speed, the glue will not go out or leaking, optional bottle is good for long time operation;

6.Folding section

*Equipped with speed variator for belts, ensure the folded boxes parallel and in good order;

*Fast, convenient adjustment and operation can fold boxes perfectly;

*The middle up and down transmission module can fold the boxes synchronously or alternately.

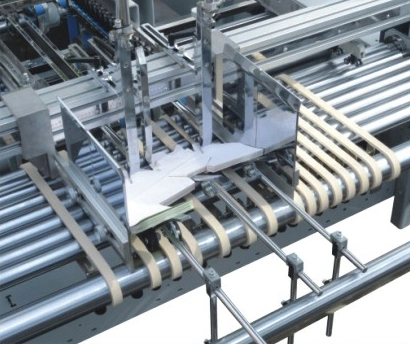

7.Trombone section

*Pressure can be adjusted according to paper thickness. For flute A, B corrugated board, overlapping and jogger devices are equipped to ensure box gluing well. After kicker is set up, whatever speed the machine runs, the kicker can automatically follow, no need to reset it.

8.Conveyor section

*Pneumatic pressure increasing, speed and pressure can be independently adjusted, pressure could be as bit increased on boxes, so the finished boxes will be more beautiful;

*The front section of conveyor can coordinated with overlapping and jogger devices to move up and down suitably.