The machine features

1.The machine is adopted international famous brand appliances and computer software.

2.The machine wallboard and inportant components are adopted aging treatment,eliminate the metal internal stress; Adopt high precision machineing centers, CNC grinding machine for grinding processing.

3.The machine shaft ,roller are adopted high quality steel, grinding processing highprecision computer dynamic balancing correction and surface hard chromium plating.

3.Machine transmission parts are adopted no-key connection,the connection eliminate clearance. It is suitable for long-term high speed with high torque.

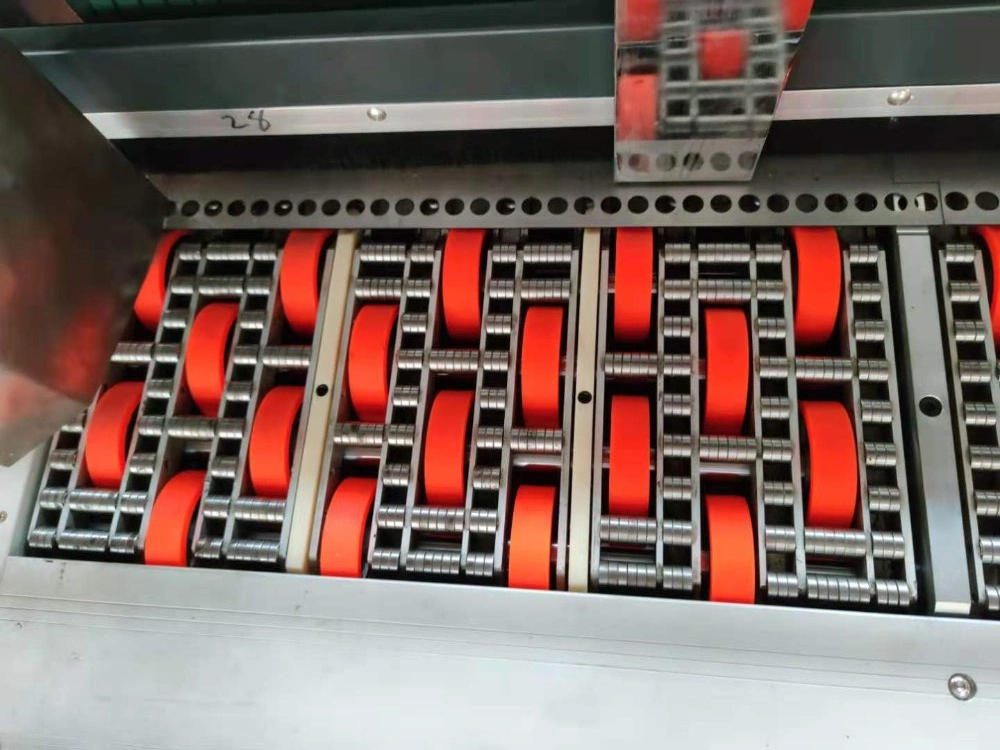

4.The machine drive bearing, important driving parts adopt international brand bearing simple maintenance, long service life, printing roll electric moves across.

Feeding Unit

1.Adopt eht servo dead edge feeder, it can feed the paper continuously or partition with the counting device.

2.The main motor adopts the frequency conversion adjusting speed motor and the speed adjustment is precise and steady with saving energy.

3.The side baffle adopts the pneumatic patting paper.

4.The main motor staring protective device, if the machine has not been locked the main motor could not start.

5.Th paperboard adopts the brush and air blower to clear the dust on the paperboard.

6.It adopts the two-rollers design and the feeding roller quick changing device.

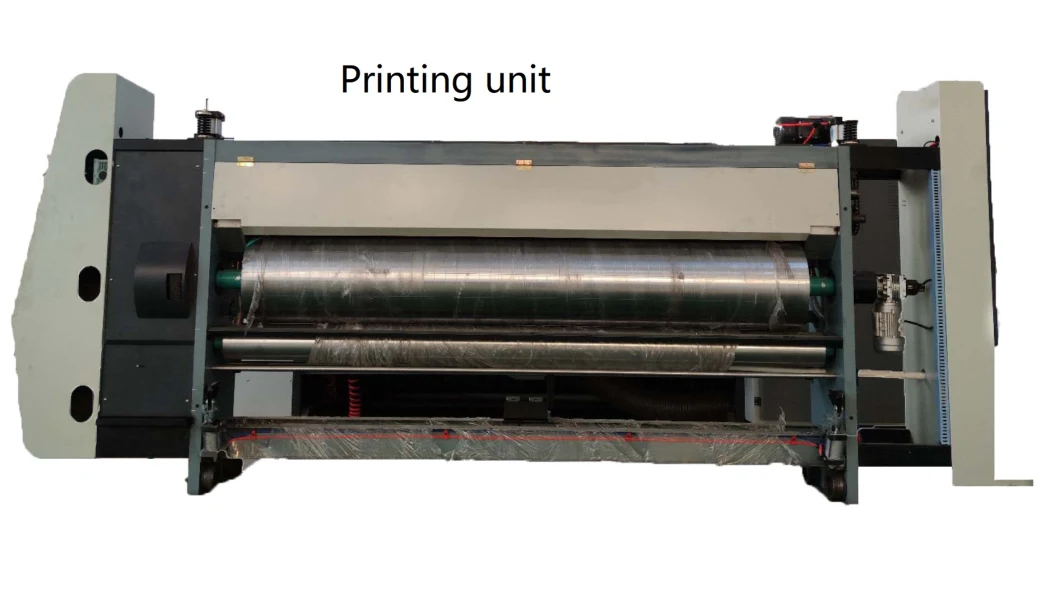

Printing Unit

1.Adpot the stell anilox roller with high precision and long using life.

2.The anilox roller adopts the clutch structure, as this unit drops out the printing, it will separate with the main drive in order to decrease the anilox roller, rubber roller, scraping knife unnecessary wear and extend the using life.

3.The quick changing structure of rubber roller and anilox roller are much more convenientand shortcut.

4.Both the rubber roller and anilox roller definite proportion drive and this structure decresses the wear .

5.The printing roller lateral movement adopts electric adjustment and the adjusting range is ±10mm.

6.The printing roller hang version function adopts two ends locking device so the version counterpoint is much precise.

7.The leading paper roller possesses the quick move

8.The printing phase adopts computer and electric digital control.

Die Cutting Unit

1.Die cutting phase adopts computer adn clectric digital control.

2.The clearance between the rubber roller and cutter mould roller adopts electric adjustment.

3.The rubber roller is equipped with the maintain knife to make sure the surface is even.

4.The rubber roller could move circularly within ±25mm laterally.